- Oscar Metal Materials

- Oscar Stainless Steel Pipes

- Oscar Elevator Parts

- Cold Drawn Guide Rails

- Machined Guide Rails

- High Speed Guide Rails

- Hollow Guide Rails

- Guide Rail Accessories

- Elevator Accessories

- Light curtain series

- fan series

- Governor machine series

- Safety Gear series

- Oil Buffer series

- Door Lock series

- Guide Shoe series

- Oil Can series

- Rose head series

- Shoe Lining series

- Repair Box series

- Switch series

- Door Slide series

- Wheel Series

- Door Knife series

- Triangle Lock series

- Walkie-talkie series

- Damping Pad series

- Station clock series

- Button series

- Power Supply Lock series

- Door machine&layer gate spare parts

- Contact series

- Operating box&handrail series

- Other series

- Equipment

- Business Relationship

- Enterprise Certification

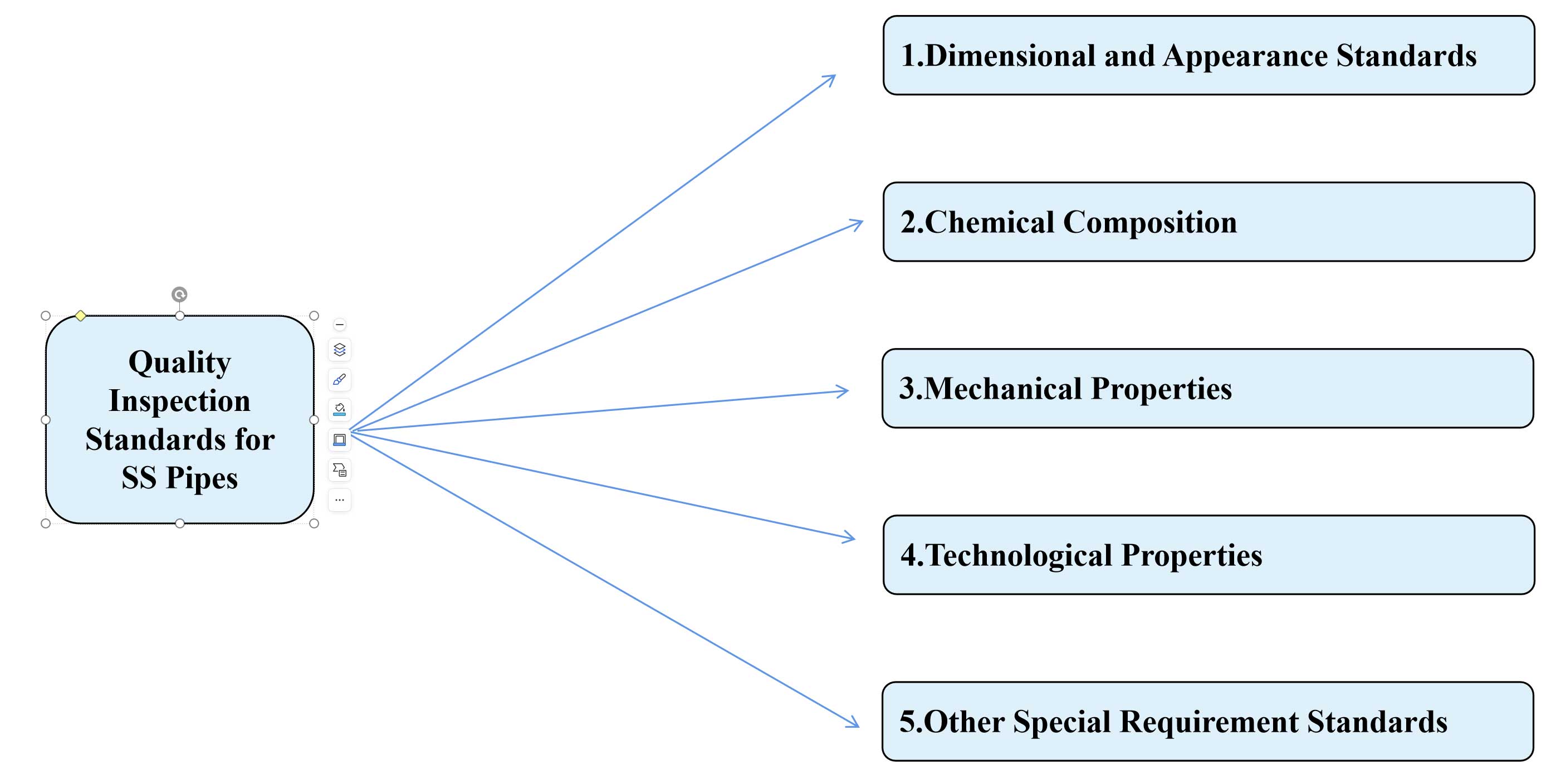

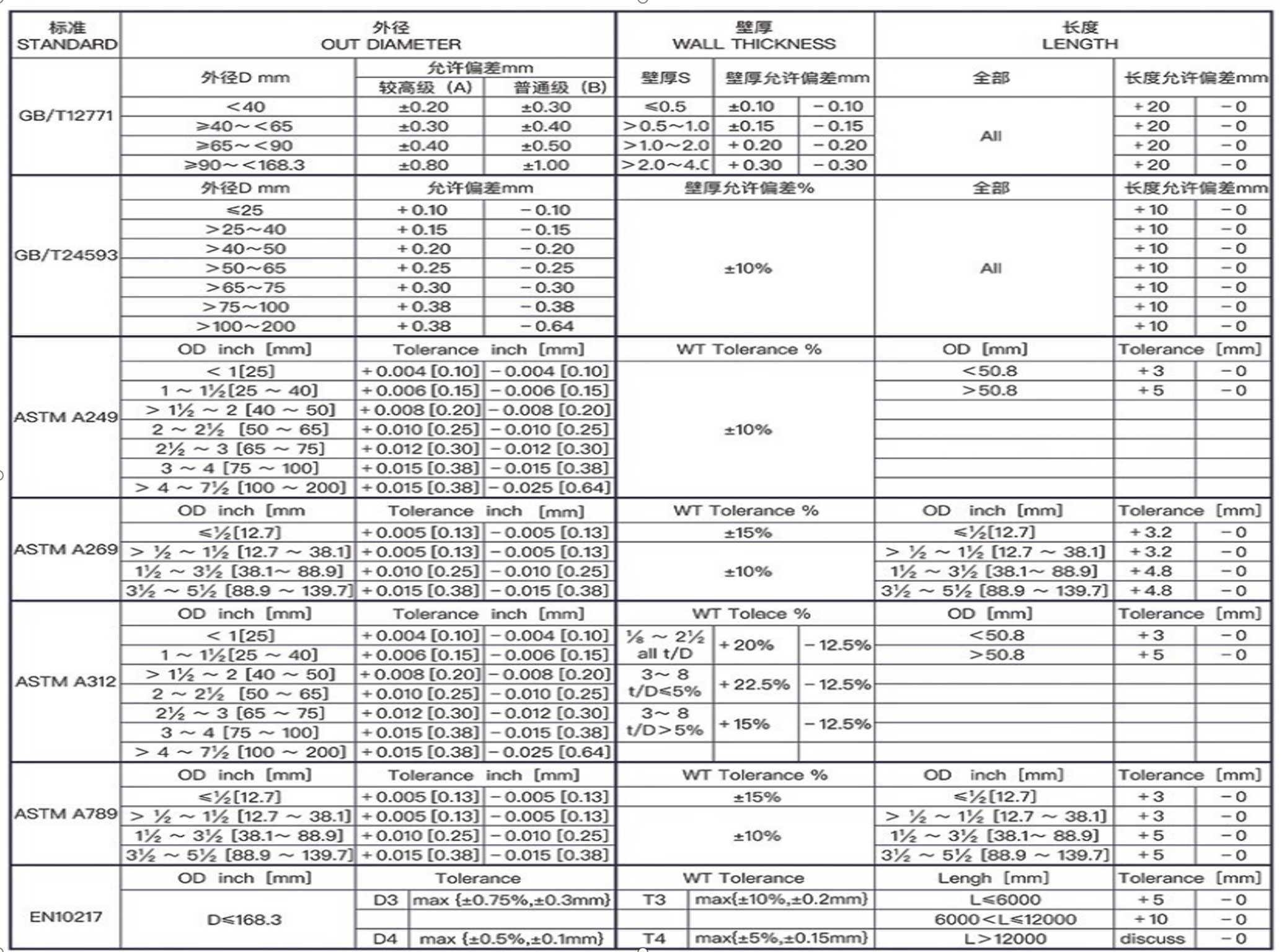

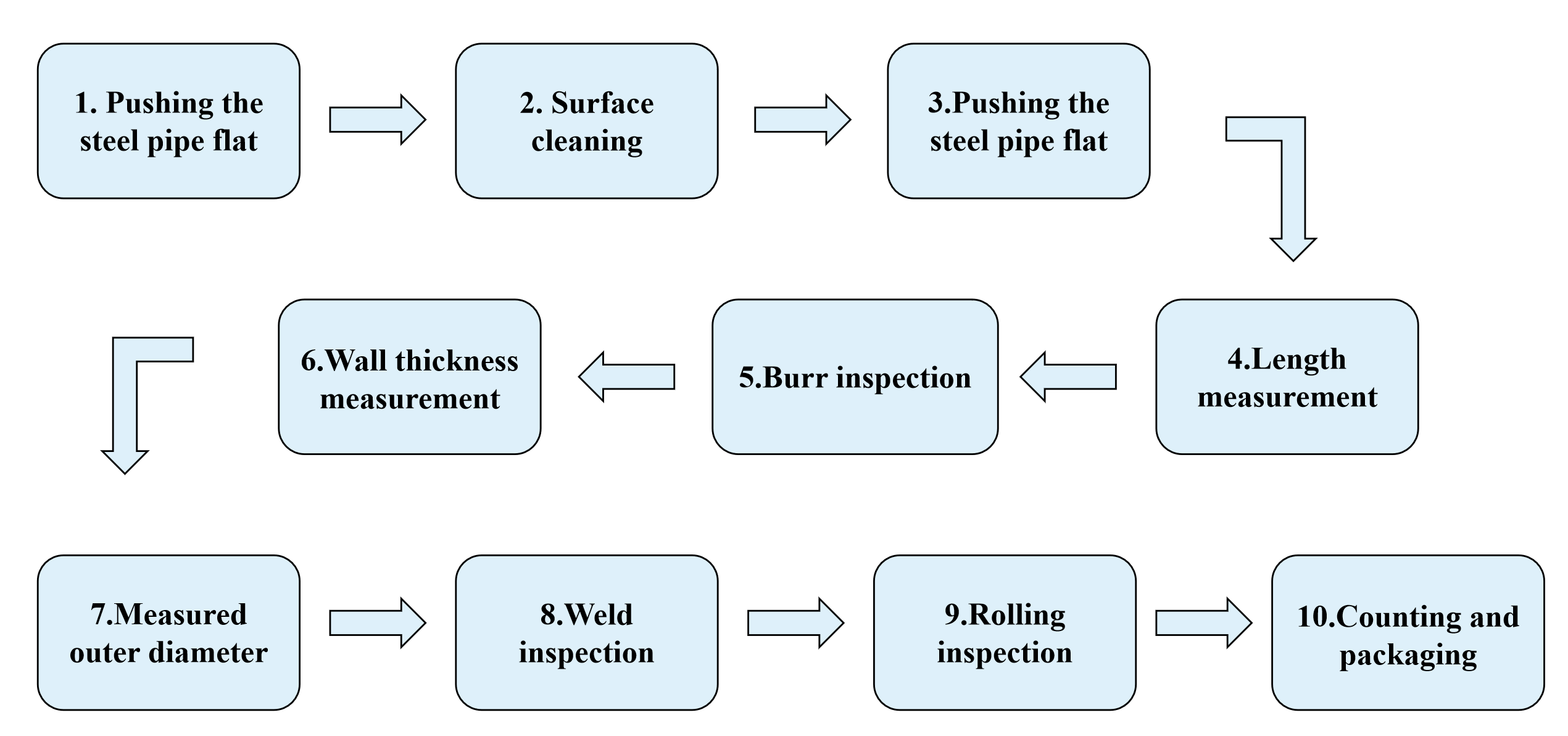

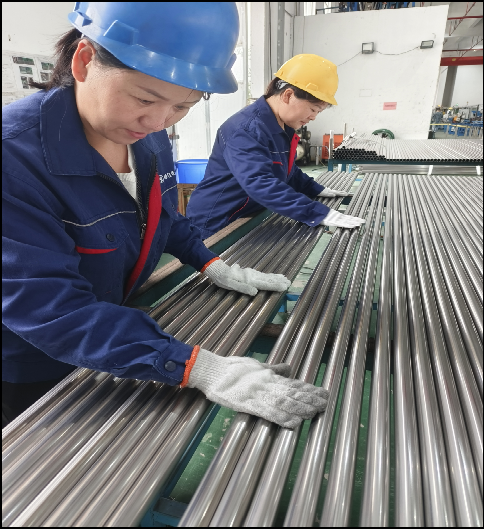

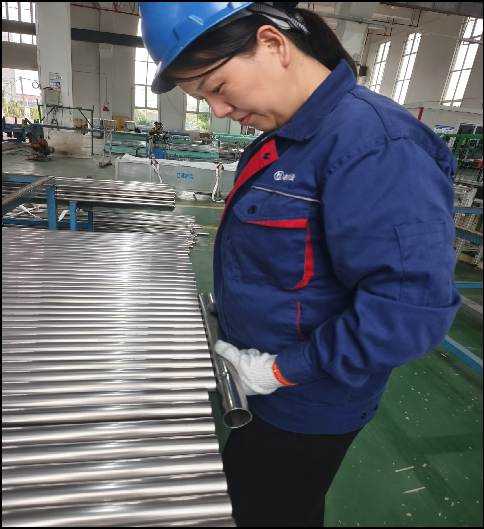

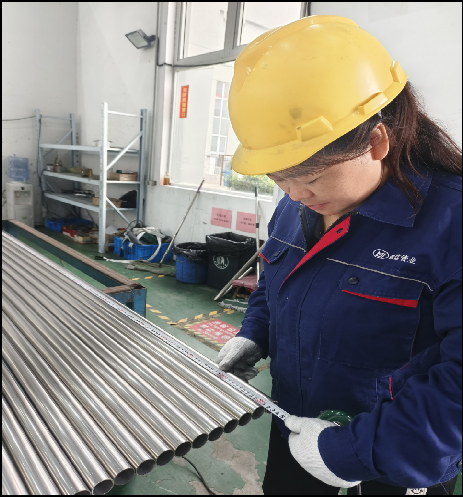

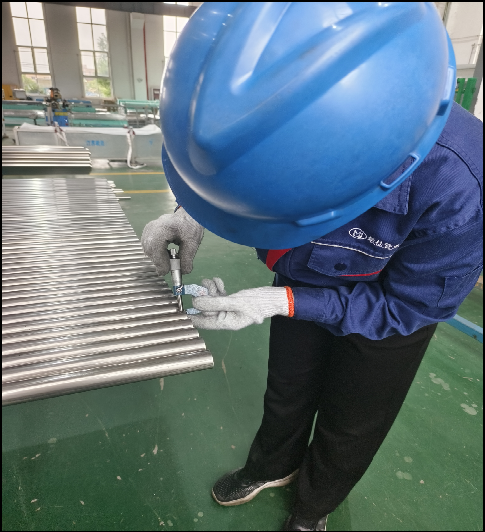

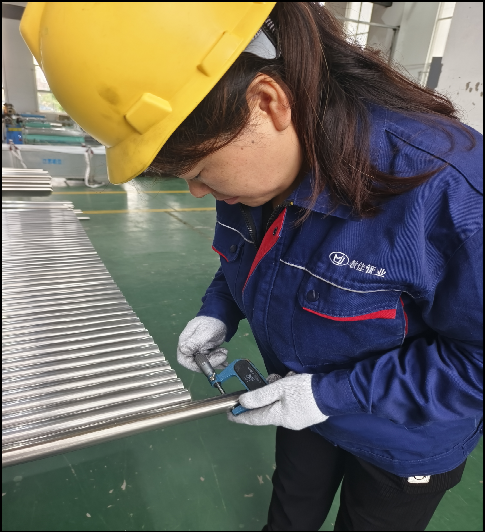

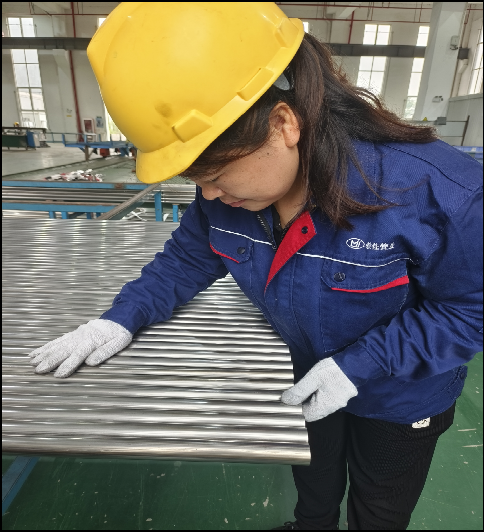

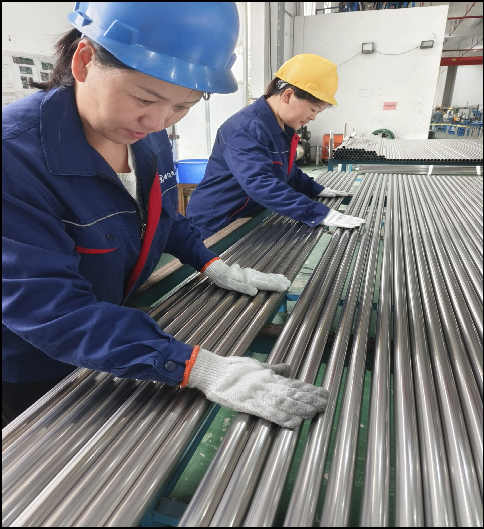

- Quality Control

- Service Assurance

- Support

Persian

Arabic

Hebrew

Czech

india

Georgian

Ukraine

Urdu

Hungarian

Indonesia

Kazakhstan

Lietuvių

Tagalog

Bangladesh

Uzbek

Vietnam

Croatian

Greek

Polish

Turkish

Finnish

Danish

Norwegian

Dutch

Italian

Deutsch

Japanese

France

Russian

Português

Español