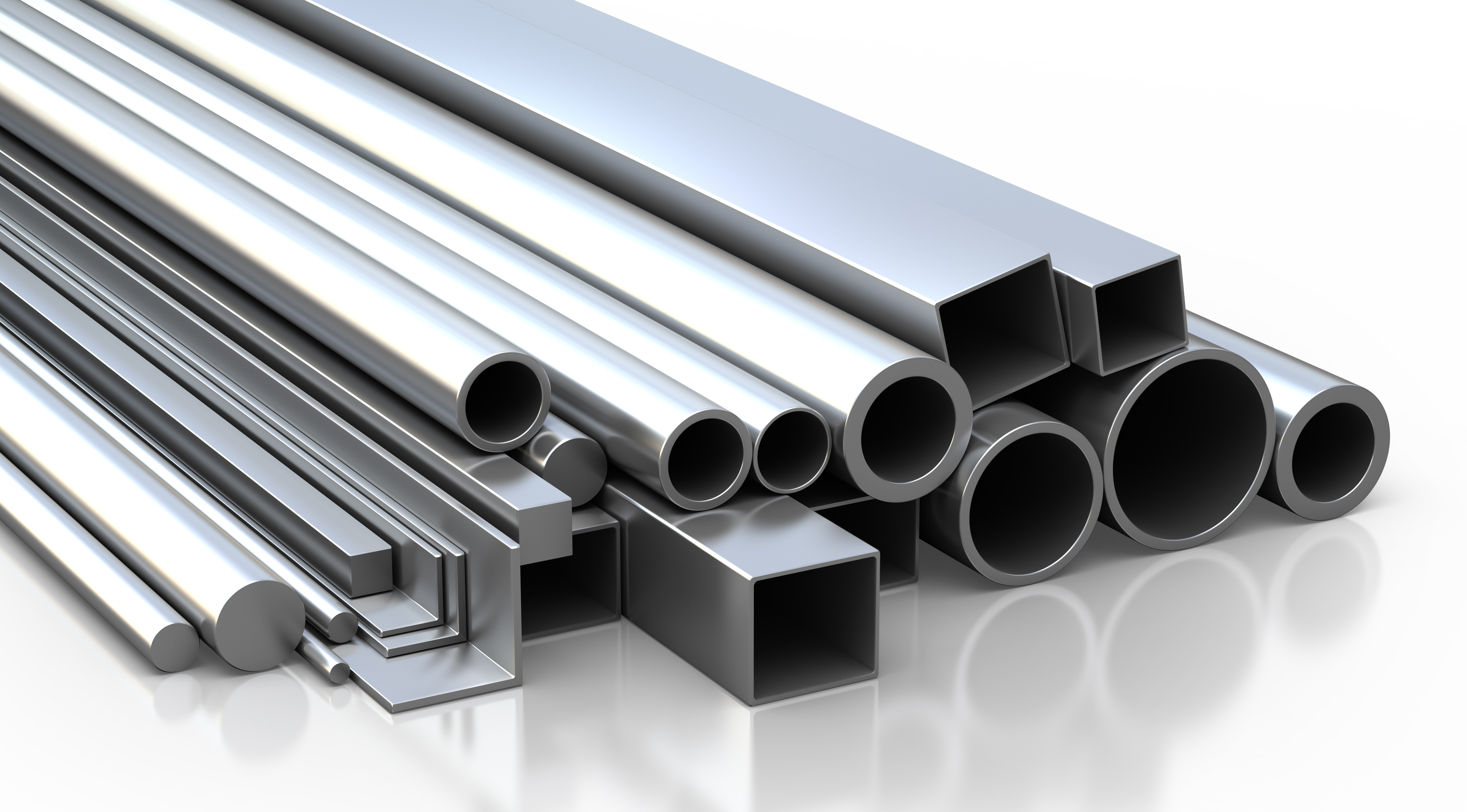

| Product Name | Representative Steel Grade | Product Specifications | Main Applications |

| Domestic Grade | International Grade | Round Steel | Square Steel | Flat Steel Steel Block |

| Gear Steel | 17Cr2Ni2Mo. 22CrMoH | 18CrNiMo7-6, SCM822H | 100-1200 | 120-1200 | (100-1200) × 1800(max) | Wind Power Speed Increaser

Industrial Reducer |

| Bearing Steel | GCr18Mo, GCr15SiMn,

G20Cr2Ni4A. G20CrNi2Mo

42CrMo,etc. | 100CrMoMoSi8-4-6.

100CrMo7-3, SAE3311,

SAE4320、50CrMo4M,etc. | 100-1200 | 120-1200 | (100-1200) × 1800(max) | Mainly used in offshore and onshore wind power bearings, large tunnel boring machine bearings, mining machinery, large industrial bearings, etc. |

| Alloy Steel | 15-50Cr. 15-50CrMo.

20CrMnTih, 20-40CrMnMo,

20-40CrNiMoA, 3Cr. Q890.

38CrMoAl, SNCM616V, EX55 | 16-20MnCr5, SCM440, AISI4130, AISI4330, AISI4140, AISI4145.

SAE8620, SAE4340, SACM645, 1E0670, SCM415, 110SS | 100-1200 | 120-1200 | (100-1200) × 1800(max) | Used for manufacturing mechanical parts and structural components that bear heavy loads. Widely applied in industries such as automotive, shipbuilding, petroleum machinery, and heavy machinery. |

30-35CMnSi, 30CrMnSiNi2A,

18Cr2Ni4WA |

| 100-1200 | 120-1200 | (100-1200) × 1800(max) | Used for manufacturing key components in the aviation industry and high-strength, high-toughness parts. |

60Si2Mn. 55~60SiMnMoV.

30W4Cr2V | SUP9 (A) , SUP11 (A) | 100-1200 | 120-1200 | (100-1200) × 1800(max) | Used for manufacturing springs and other elastic components. |

Hot Work Tool Steel

| 521, DYH13, YGH13,

YG811 YGDVA. YGH585,

DG-01, DG-02, YG-DG50.

YG-DG55, 4Cr5MoSiV.

4Cr5MoSiV1, 4Cr5Mo2V,

4Cr5Mo3V, 5CrMnMo,

5CrNiMo, 5CrNi2MoV..... | H11, H13, H21, 1.2343,

1.2344、1.2367、1.2714、

8407, 8418, L6, 55NiCrMoV7.

X40CrMoV5-1, SKD61 | 12-1000 | 120-800 | (100-800) × 1100(max) | Extrusion molds for aluminum profiles, die-casting molds for aluminum, magnesium, and zinc alloys, forging molds for automotive connecting rods, crankshafts, flanges, hot stamping molds, tunnel boring machine tools, etc. |

| Plastic Mold Steel | 3Cr2Mo. 3Cr2NiMo, 4Cr13.

4Cr13NiVSi, 3Cr17NiMo.

1Ni3MnCuMoAl...... | P20, 718, 1.2738, 1.2311,

1.2312, 1.2316, S136, NAK80 | 12-1600 | 120-1200 | (100-1200) × 1800(max) | Used for large mold frames and molds in industries such as automotive and home appliances, high-grade mirror precision molds, and high-grade mirror corrosion-resistant molds, etc. |

| Cold Work Tool Steel | Cr5Mo1V, Cr12MoV.

Cr12Mo1V1, 7Cr7Mo2V2Si(LD).

Cr8Mo2SiV….. | D2. SKD11, A2. 01. 02.

DC53. S1, 1.2379 | 12-600 | 120-500 | (80-500) x 600(max) | Used for manufacturing cold stamping dies, drawing dies, thread rolling dies, cold heading dies, cold extrusion dies, and cold rolling rolls that require high hardness, strength, and wear resistance. |

| Stainless Steel | 0Cr18Ni9, 00Cr19Ni10,

0Cr17Ni12Mo2, 00Cr17Ni14Mo2.

0Cr18Ni9Ti, OCr18Ni11Nb | 304, 304L, 316, 316L.

321、347 | 12-500 | ≥45 × 45 | Rolled Flats: 10-60 × 20-150

Forged Flats: >60 × 120 | Stainless Steel Tube Billets

Stainless Steel Utensils |

1-4Cr13, 1Cr17Ni2, Y1Cr13,

9Cr18, 05Cr17Ni4Cu4Nb.

05Cr15Ni5Cu4Nb, OCr13Ni8Mo2Al,

1Cr11MoV, 1Cr11Ni2W2MoV.

1Cr12Ni2WMoVNb, 2Cr12NiW1Mo1V,

1Cr16Co5Ni2MoWVNbN,

1Cr15Ni4Mo3N, OCr11Ni2MoVNb | 410, 420, 431, SUS416, 440.

450、

17-4PH, 15-5PH, MX-13,

9Cr. 13Cr. S13Cr | 12-800 | ≥45 × 45 | Rolled Flats: 10-60 × 20-150

Forged Flats: >60 × 120 | Blades, petroleum components, valve bodies, heat-resistant and corrosion-resistant parts |

| Ultra-High Strength Steel | 40CrNi2MoA, 30CrMnSiNi2A,

40CrNi2Si2MoVA, 45CrNiMo1V,

16Cr3NiWMoVNbE, 18CrNi4A, D6AC,

30Ni4CrMo, 35Cr2Ni4MoA, D6AE,

30Cr3SiNiMoV, 30 (31) Si2MnCrMoVE,

8Cr4Mo4V, Cr14Mo4V, G13Cr4Mo4Ni4V,

16Co14Ni10Cr2Mo, 23Co14Ni12Cr3MoE,

Martensitic Aging Steel, etc. | SAE4340, SAE4330, 9310.

SAE4130. 300M, M50.

M50Nil,etc. | 12-600 | ≥45 × 45 | Rolled Flats: 10-60 × 20-150

Forged Flats: >60 × 120 | Structural components for aerospace products; steel for aviation bearings, rocket engine casings |

| High-Temperature Alloy | GH4169, GH4698. GH4141.

GH5188. GH2909, GH4738.

GH4648. GH4080A, GH4133B.

GH3536, GH2901, GH2150.

GH3039, GH3044, GH3230.

GH4145. GH4099, GH6783 | Inconel718, эи698, Rene41, Hastelloy188, Incoloy909.

Wasploy, эи648, N80A.

Hastelloy X. Incoloy901.

InconelX-750 | 12-450 can be used for forging (such as square and flat bars, stepped shafts, etc.) | Key materials for hot-end components in aerospace, gas turbines, and power stations, used to manufacture turbine discs, compressor discs, blades, load-bearing rings, sealing rings, and casings. |

| Corrosion-Resistant Alloy | NS111, NS112. NS142.

NS312. NS334, NS336 | Incoloy800, Incoloy800H, N08825.

N08028. N06625, UNS N07718.

UNS N09925, UNS N06985(G3).

UNS N06690, UNS N06600.

Monel400, C276, A286, HR-120 | 12-700 can be used for forging (such as square and flat bars, stepped shafts, etc.) | Used for manufacturing corrosion-resistant core components in petrochemical, energy, and nuclear power industries. |

| Note: Based on the steel grade and specification, products can be delivered according to customer requirements in forged or heat-treated conditions, with surface finishes such as black surface, machined, or peeled by grinding wheel (for bars). |